- Panoramica

-

Scarica il Rilevatore

- A proposito del Blu-ray

-

Funzionalità Blu-ray

-

Tecnologie dischi Nuova Generazione

-

Specifiche tecniche Blu-ray Disc

-

Link Utili

- A proposito del Blu-ray 3D

-

Come funziona il 3D?

-

Cos'e' il Blu-ray 3D?

-

Come si prepara un home theater sul PC?

-

Visione 3D sul PC

-

Scarica il white paper 3D

Next-Generation DVD Technologies

An overview

Let's first take a look at some of the factors which allow optical discs to store so much data.

The Optics

First we have the laser light used to burn and read data from an optical disc. Closely linked to the laser light is the lens used to focus the laser light on to the disc. The parameters that influence how much data can be stored on a disc are the wave length of the laser light and the so called numerical aperture of the lens.

You may already know that the wavelength of light and its color are somehow linked. Lower wavelength light tends towards the color red while higher wavelength light tends towards blue or violet (see infrared and ultraviolet). However, the numerical aperture may be new to you. The numerical aperture (NA) of an optical lens in our case is the ability of that lens to focus light on a specific point at a specific distance - small distances result in larger NA values.

The greater the NA and the shorter the laser wavelength, the smaller the point of focus (higher precision) will be. The tiny circle of laser light that hits the data track during recording and creates the tiny holes representing bits is called the laser beam waist. The radius of the beam waist is the laser light wavelength divided by the numerical aperture. That is why you will get smaller "data holes" if the laser wavelength is smaller and the NA is larger. This also means that the distance between two tracks of data (Track Pitch) on an optical disc can be smaller.

The track pitch refers to the distance between two data tracks on an optical disc. Data on an optical disc is stored similar to the spiral track on an old record except that the spiral starts in the center.

The actual data on a disc is stored (burnt) in form of tiny holes or "pits" along the data track. Pits are separated by areas along the data track called "land". Laser light gets reflected from the series of pits and is then interpreted as 0s and 1s. If the minimal possible pit length get smaller then more data can be squeezed onto a disc. The minimal possible pit length depends on the size of the beam waist when it hits the data track.

The Disc

The optical disc itself is also another vital factor in the equation. For instance, the thicker the protective coating on the disc and the deeper the data layer is embedded the more powerful the laser will have to be and the more energy the optical drive will consume.

A thicker layer also means a greater distance between lens and data layer, so the numerical aperture will be smaller, the point of focus larger and hence the distance between data tracks wider. On the other hand, if the protective layer is thinner and the data layer closer to the surface then the numerical aperture will be larger and more data can be stored on the optical disc.

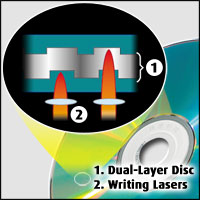

A disc can also contain multiple layers of data, dependent on how thick the optical disc is. In conventional DVDs we see this with dual-layer discs, which can hold roughly twice the capacity of a single layered disc.

Let's look at the distance between the lens and the data layer. We all know that CDs and DVDs will behave badly if scratched or covered with dust. The closer the lens is to the optical disc surface and, coming from the other direction, the closer the data layer is to the surface the more susceptible the disc will be to dust and scratches. So a thick or strong protective layer is required.

Other Factors

Okay, compression may not be directly linked to the disc or the burner itself, but more to software algorithms; however the compression techniques supported by optical disc specifications also play a role. The better the compression techniques supported the more data can fit onto the disc.

Data transfer rates on optical discs are dependant on some of the above mentioned features, such as minimal pit lengths, and also how fast the optical disc spins. The quicker it spins the faster data can be burnt to or read from it. If the pit lengths are smaller the quicker it takes to read or burn data.

Burning

Now we are ready to talk about how burning works. Recordable discs are simply discs which contain an "empty" data track. A reflective data layer is covered by a dye that is sensitive to light. During burning the dye is burnt so that reflective pits are created. In some ways you can think of this as a similar process to photography or to how circuit boards are created.

While on a recordable disc it is not possible to reverse the process, the data layer of rewritable discs is covered with a special type of metal (alloy) which can be changed back to its original state (erased) after it has been burnt. The metal alloy changes how it reflects light based on the heat of the write-laser during burning. This is how "pits" are generated. During erasing the metal alloy returns to its original state.

So that basically wraps up everything you will need to know about the basics. We are now ready to have a closer look at Blu-ray discs.